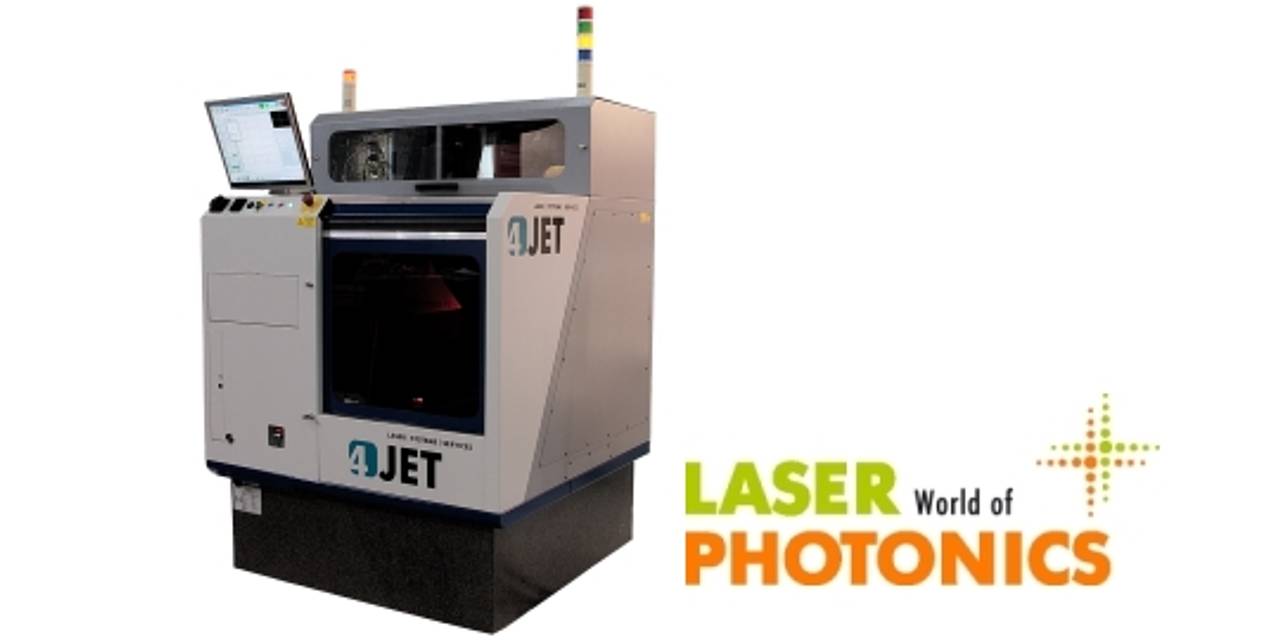

4JET microtech GmbH & Co. KG presents its new CUBE micromachining tool during LASER 2017 in Munich.

Targeting laser applications “on or in glass” the system allows to structure thin-films, cut or drill glass and other brittle materials. Fixed beam and galvo scanner options also enable other materials processing application.

- Cutting

- Drilling

- Patterning

Key applications include laser processing glass wafers or substrates for electronic, optical or medical applications. However, the system can be easily reconfigured for other processing applications in industry or R+D.

The granite motion system with a repeat accuracy of better 2 µm in all three dimensions combined with CCD alignment cameras as well as an offset detection guarantee for a part accuracy in the single digit micron range.

Substrates up to 600 x 600 mm2 can be processed. Workpiece trays allow automatic cassette loading.

Key design objectives of the system – besides economical pricing – were a compact size and quick ramp-up times. Therefore laser source and controls are embedded in the machine enclosure.

The 4JET control suite allows easy import of CAD files and CAD to G-Code conversion. Other features include auto calibration, a vacuum chuck with integrated debris collection as well as an integrated laser power measurement.

Several of the new CUBE systems will be installed in 2017.